We know the energy transformation in solar panels, so if we can improve the crystalline silicon solar cells, we will make significant progress in using solar energy. In fact, in the past decade, scientists have always tried hard to fulfill them. Here are some successful Stories of Efficiency Improvement in Crystalline Silicon Solar Cells

- Passivated Emitter and Rear Cell (PERC) Technology: From Lab Curiosity to Industry Standard

- The Idea: PERC involves adding a passivation layer (often a thin film of aluminum oxide or silicon dioxide) on the rear surface of the solar cell. This layer reduces surface recombination, essentially electrons and holes (the carriers of electricity) getting “lost” at the back surface before they can contribute to the current. It also helps reflect unused light into the silicon for another absorption chance.

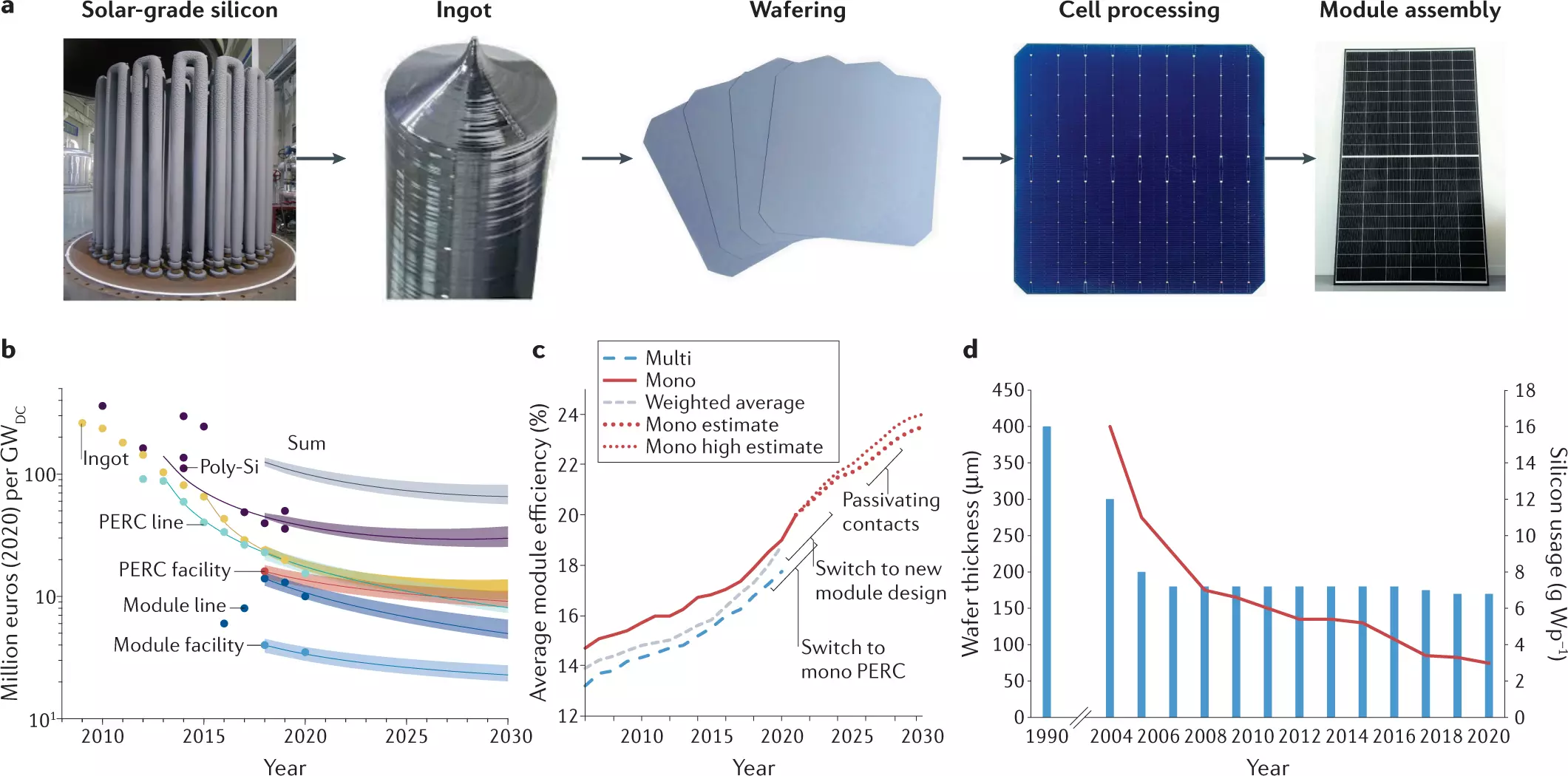

- The Success: PERC technology has been hugely successful because it’s relatively simple to implement in existing manufacturing lines, offering a significant boost in efficiency (around 1-2% absolute gain) at a reasonable cost. Most crystalline silicon solar cells today incorporate PERC or its variations (like PERT, which passivates both the front and rear surfaces).

- Why it Matters: PERC has been a game changer for the entire solar industry, leading to significant cost reductions in solar electricity production. It demonstrates the power of surface passivation in enhancing cell performance.

- Heterojunction Technology (HJT): The High-Efficiency Champion

- The Idea: HJT solar cells are built using a crystalline silicon wafer surrounded by layers of thin-film amorphous silicon. These layers create heterojunctions, which provide excellent surface passivation. HJT also allows for better light absorption and higher open-circuit voltages (which contribute significantly to higher power output).

- The Success: HJT cells often achieve significantly higher efficiencies than standard PERC cells (typically exceeding 23% and reaching over 26% in lab settings). Companies like Kaneka and REC Group have successfully commercialized HJT modules with impressive performance.

- Why it Matters: HJT is a leading candidate for the next high-efficiency crystalline silicon solar cell generation. While more complex and initially more costly to manufacture than PERC, continued development lowers production costs and solidifies HJT’s place as a premium, high-performance option.

- Interdigitated Back Contact (IBC) Cells: Streamlining for Performance

- The Idea: IBC cells move both the positive and negative contacts to the back of the cell. This eliminates the shading caused by front-side metal grids, allowing more sunlight to reach the silicon. Also, back contacts simplify module manufacturing, reducing the cell-to-module loss.

- The Success: IBC cells are known for their high efficiency and aesthetic appeal (due to the absence of front-side metallization). SunPower’s Maxeon cells are a prime example of the successful commercialization of IBC technology.

- Why it Matters: IBC demonstrates the importance of cell architecture. By rethinking how the cell is structured, significant gains in efficiency can be achieved. While often more expensive to manufacture than PERC, IBC cells offer top-tier performance in efficiency and durability.

- Tunnel Oxide Passivated Contact (TOPCon): An Emerging Winner

- The Idea: TOPCon technology involves creating an ultra-thin tunnel oxide layer sandwiched between the crystalline silicon and a doped polysilicon layer. This structure provides excellent surface passivation and allows for efficient carrier extraction. It’s similar to PERC but provides even better contact passivation.

- The Success: TOPCon is rapidly emerging as a promising technology for high-efficiency silicon solar cells. It offers a good balance between performance, cost, and manufacturability. Numerous companies are investing heavily in TOPCon production lines.

- Why it Matters: TOPCon is expected to become a dominant technology shortly, further pushing the boundaries of crystalline silicon solar cell efficiency. Its relatively simple integration into existing manufacturing infrastructure makes it an attractive option for many manufacturers.

Common Threads in These Success Stories:

- Surface Passivation: Reducing electron-hole recombination at the silicon surface is crucial.

- Light Management: Capturing and utilizing as much sunlight as possible is essential.

- Process Optimization: Efficient and cost-effective manufacturing processes are key.

- Continuous Innovation: Ongoing research and development are vital for further improvements.

These examples demonstrate that a combination of clever designs, advanced materials, and optimized manufacturing techniques can significantly improve the efficiency of crystalline silicon solar cells, making solar energy more affordable and accessible.